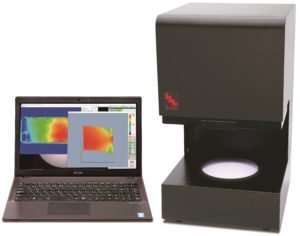

LSM-9001NIR

Evaluate strain with 2D distribution of low phase difference samples such as semiconductor wafers, colored glass, and colored acrylic resin products.

Evaluate up to approx. 50 x 50 mm in 1 minute.

<Model name>

Fully Automatic Strain Eye LSM-9001NIR

<Inspection method>

NIR Rotating Analyzer Method

* Fully automatic measurement reduces work and measurement errors by the measurer.

Simply place the object to be measured and click the measurement button. It is possible to get the measurement results with the information captured by the built-in camera. Since no judgment by the measurer is required, measurement errors caused by such judgments are eliminated.

* This is capable of performing strain evaluating of semiconductor wafers, colored or transparent products, residual stress, and cracks that are impossible to measure with conventional polariscope.

* Software analysis tools

Graphs of cross sections on 2D distribution maps, histograms of arbitrarily set areas, 3D display of 2D distribution maps, csv storage of measurement results, and image storage. These functions are included in the software. They are useful for analyzing evaluation results.

* Long life and power saving

High-Luminance LED is used as the light source. This reduces maintenance time and running costs related to light source replacement.

Specification

| Inspection Method | NIR Rotating Analyzer Method |

| Measurement Range (approx.) | 0~150nm (Retardation) |

| Measurement area size | (approx.) 50×50mm |

| Measurement object placement space (height) | Max 160mm |

| Size | W300 ☓ D353 ☓ H540 mm |

| Weight | 22 kg |

| Others | Light Source:high-luminanceLED PowerSorce:AC100~240V 50/60Hz DC input 24V 1.6A Component:Mainbody,PC,Cables Accessory:Main body cover OS:Windows10 Pro (64bit) Japanese/English |