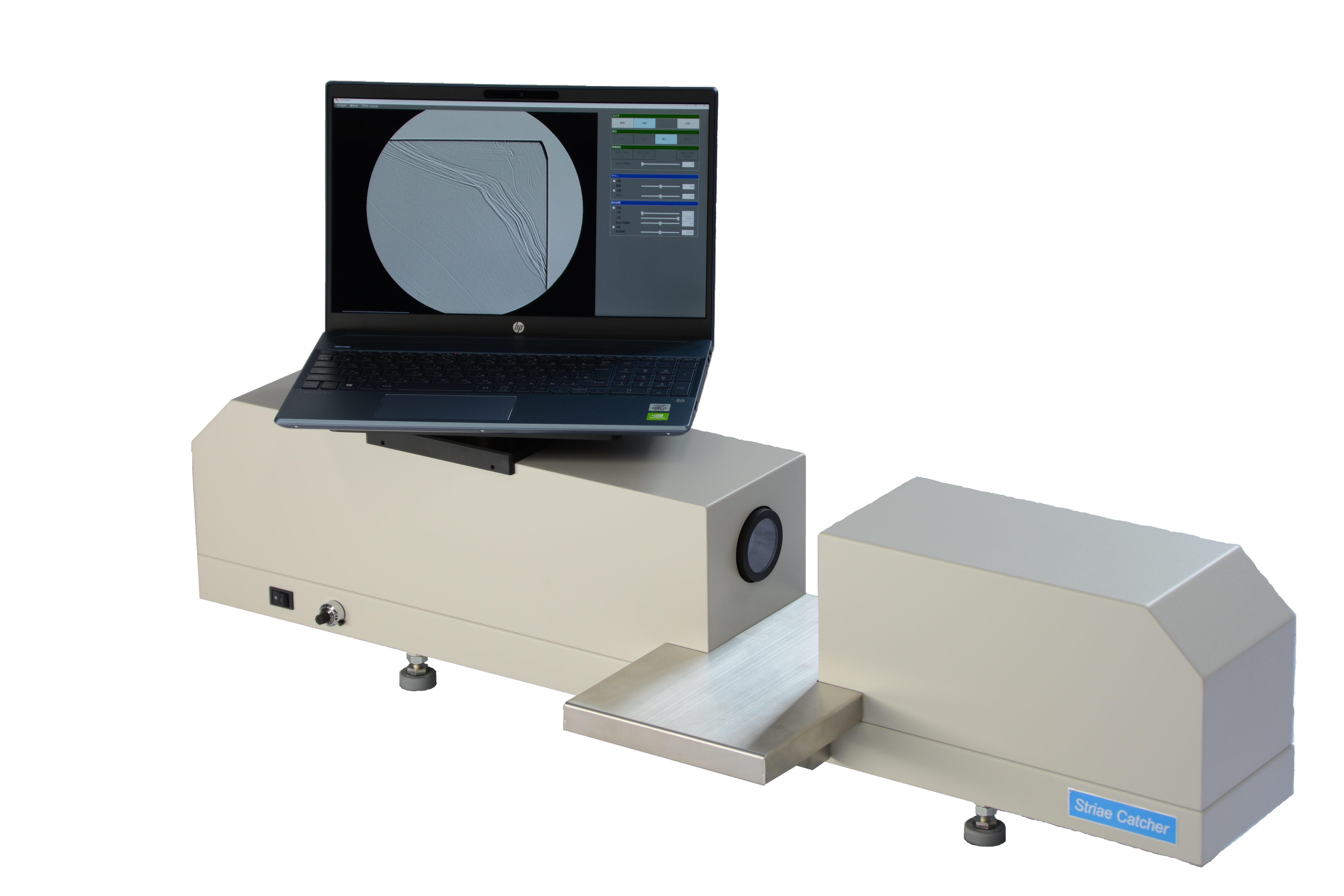

Striae inspection device

This inspector is an instrument for visualizing striae and uniformity of transparent materials. It is suitable to inspect crystals and blue filter for low pass filter built-in camera.

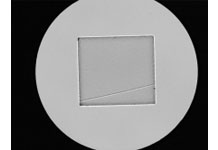

There is a light spot pattern on the background of the observation image. This is derived from the surface polishing of optical elements such as the lenses that are mounted, which has hindered the observation. The dedicated software “ClearBack” makes the background clearer and makes the inspection easier.

There is an observation method called Schlieren method for the visualization apparatus of refractive index change, but the observation method of this apparatus is shadow graph method, avoiding blurring of images due to interference occurring at the knife edge.

There is a light spot pattern on the background of the observation image. This is derived from the surface polishing of optical elements such as the lenses that are mounted, which has hindered the observation. The dedicated software “ClearBack” makes the background clearer and makes the inspection easier.

There is an observation method called Schlieren method for the visualization apparatus of refractive index change, but the observation method of this apparatus is shadow graph method, avoiding blurring of images due to interference occurring at the knife edge.

Video guide of inspection

Specification

| Inspection Method | Shadowgraphy method It means “shadowgraph” as the name indicates. After passing the 1st lens, diverging light from spatial filter changes to parallel light. Parallel light changes to convergent light through the 2nd lens, and is taken a picture by CCD camera. When the sample with striae is put between 2 lenses, the parallel light isn’t uniform. And the non-uniform brightness is taken by CCD camera. |

| View field | Approx. φ45 mm |

| Light source | High brightness LED |

| Effective pixels | 1080(H)×824(V) |

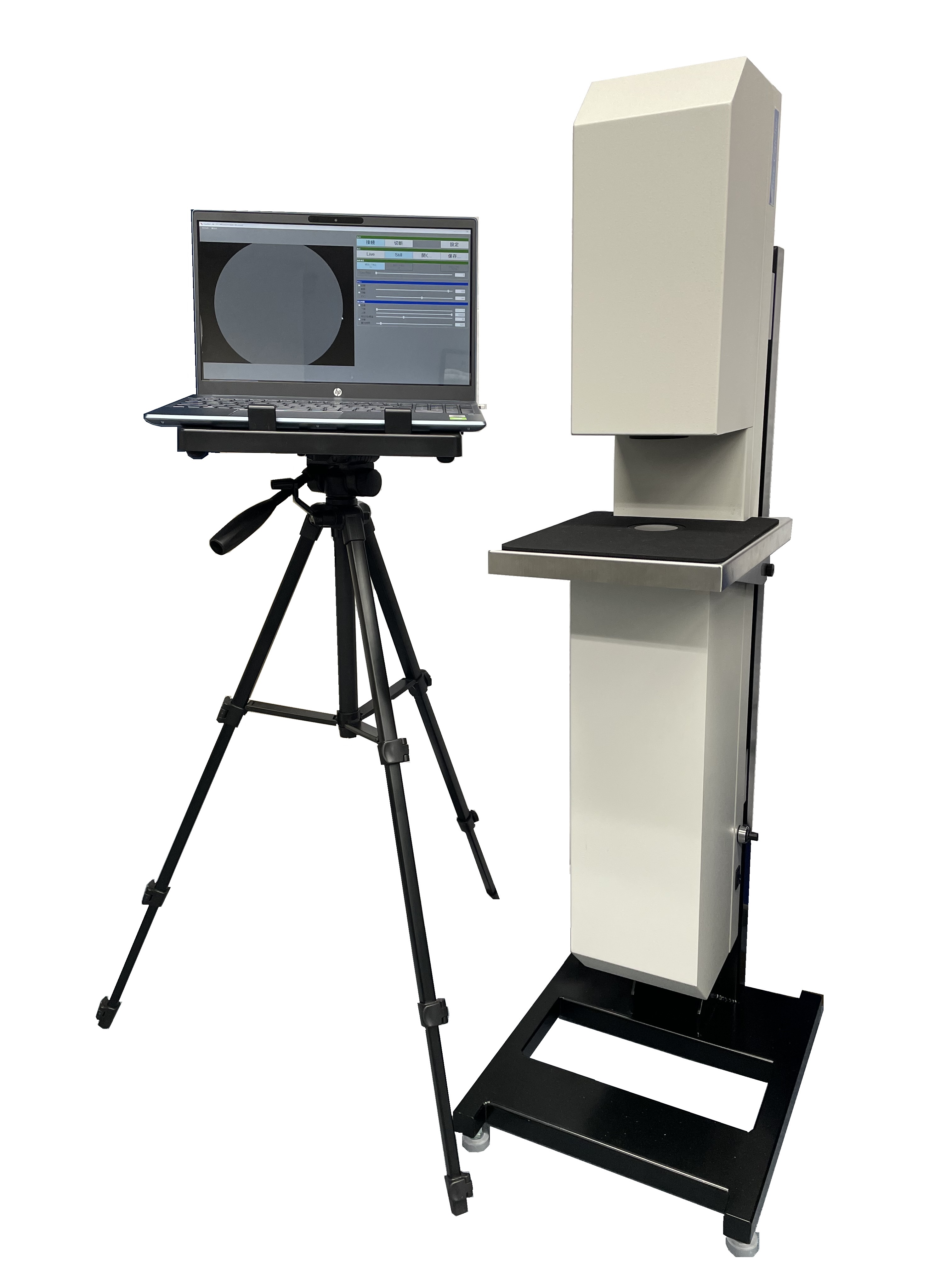

| Option | Vertical stand (Weight:10kg) |

| PC | Windows 10(64bit) |

| Size | Standard:W1030 x D160 x H205mm (Weight:29kg) Vertical stand (Optin):W380 x D455 x H1245mm |

| Software | Dedicated software “ClearBack” This software makes the background uniform by correcting image brightness unevenness. This makes it easier to check for defects. |